|

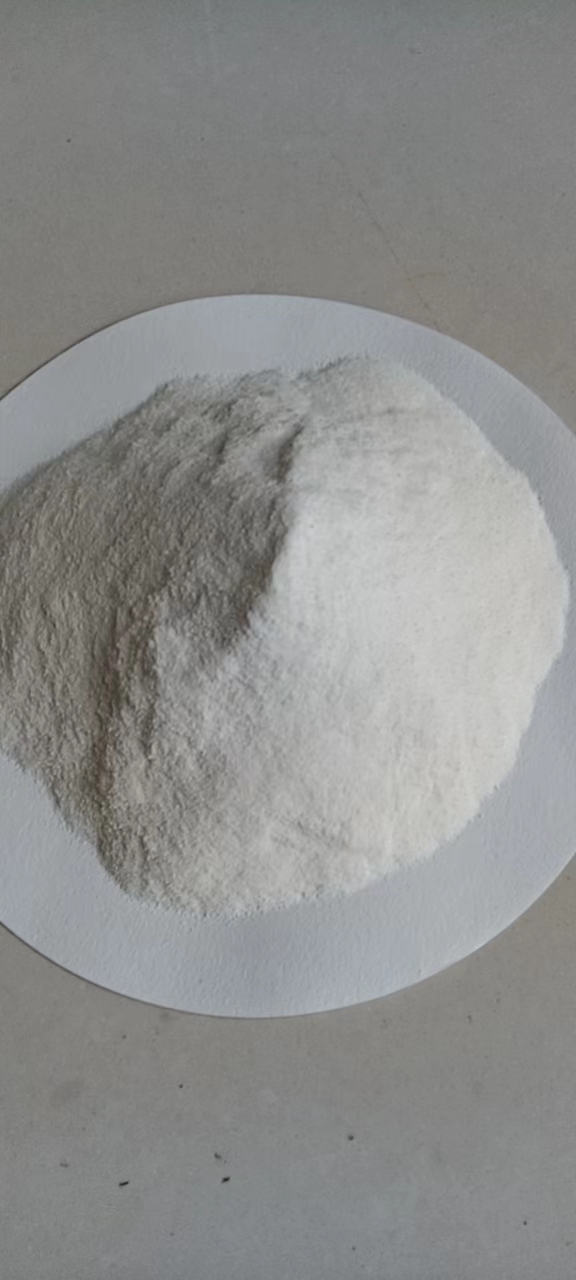

Hydroxypropylmethylcellulose

Collect

HydroxypropylmethylcelluloseProduct introduction Hydroxypropylmethylcellulose It is divided into three types of water-soluble cellulose ethers: methylcellulose, hydroxypropylmethylcellulose, and hydroxyethylmethylcellulose. These products are formed by replacing part of the hydroxyl group with methyl, hydroxypropyl or hydroxyethyl groups. Hydroxypropyl methylcellulose is used in building materials, coatings, chemicals, personal care, medicine and home decoration, etc.

Proper application of hydroxypropyl methylcellulose products can: Improve the construction efficiency of mortar and realize mechanized construction, thereby saving time and materials; Produce high-quality mortar products and give mortar new functions; Improve the adaptability of mortar to the application environment. Main performance Water retention: When hydroxypropyl methylcellulose is applied to the surface of water-absorbent materials such as walls, it has the property of effectively reducing water loss. Water solubility: Hydroxypropyl methylcellulose is easily soluble in cold water, but insoluble in hot water. Organic solubility: The unique hydrophobic functional group in hydroxypropyl methylcellulose enables it to be dissolved in some organic binary entities and solvents with accumulated water. PH Stability: Hydroxypropyl methylcellulose PH The value is generally stable in the range of 3.0-11.0. The solubility of hydroxypropyl methylcellulose is affected by pH. Non-ionic substitution: Hydroxypropyl methylcellulose is compatible with other additives in aqueous solutions and provides a stable water-soluble combination. Thickening and Adhesion: Solutions of hydroxypropyl methylcellulose have thickening and adhesion-enhancing properties. Suspension: Hydroxypropyl methylcellulose can improve the suspension stability of the solution. Thermal gelling property: When the temperature rises to a certain level, the hydroxypropyl methylcellulose aqueous solution will gel. When the solution temperature drops, the gelation phenomenon will disappear. Lubricity: The properties of hydroxypropyl methylcellulose improve workability, processability of cement-based products and extrusion properties of ceramic tiles. Surface activity: The surface activity of hydroxypropyl methylcellulose provides the required protective colloid and emulsification in the solution. Film-forming properties: Hydroxypropyl methylcellulose can form a transparent, flexible and strong film that can effectively block grease. Antibacterial and anti-mildew degeneration: During long-term storage, hydroxypropyl methylcellulose can effectively prevent bacterial invasion, so it can ensure good viscosity stability. Emulsification: Hydroxypropyl methylcellulose stabilizes emulsions in its solution. Hydroxypropyl methylcellulose is a very important component in building materials. It enables cement, lime lime and gypsum-based systems to achieve better water retention, strength and adhesion. It also makes the industrial production of high-quality mortar products possible. The main purpose Interior and exterior wall putty: HPMC The excellent water-retaining properties prevent the putty powder from cracking due to drying too quickly after scraping. It enhances the strength after hardening and facilitates scraping construction. Because of its viscosity, it also plays a role in assisting in improving the bonding force. Ordinary mortar: add appropriate amount HPMC It can make the mortar even and full, apply smoothly, not stick to the knife or sag, promote better hydration of the mortar cementitious material, and improve the later strength of the mortar. Tile bonding mortar: HPMC Good water retention, enhanced adhesion, and high sag resistance improve the efficiency of tile adhesion, which can greatly improve the construction performance of the adhesive, allow longer opening time and stronger adhesion, and prevent excessive water loss of tiles. Quickly falls off, improving bonding strength and shear strength. Gypsum-based plaster: HPMC It can retain the moisture in the mortar, allowing the gypsum to be completely solidified. Its anti-sag properties allow builders to apply thicker coatings without causing building ripples. Mechanical spray plastering: HPMC It can make the shotcrete have good pumping performance and sag resistance, extend the operable time, improve the ease of mortar and avoid mortar delamination and pipe blockage. Cement-based self-leveling and grouting materials: low viscosity HPMC Anti-sedimentation, enhanced fluidity and pumpability. Its water retention prevents bleeding and segregation, and reduces cracking and shrinkage. Packaging, transportation and storage The product is packaged in composite bags, with a net weight of 25 per bag kg。 When storing, store in a ventilated and dry place indoors, and pay attention to moisture-proof. Pay attention to rain and sun protection during transportation. statement: The applicable scope, usage conditions and suggestions of Furman Group products are formulated based on the company's latest technology and experience. They are based on normal conditions and appropriate storage, handling and appropriate use. Due to the actual application of raw materials and coordination Due to different conditions of use, the conditions stated in this product brochure, written suggestions and other advice do not guarantee product performance and applicability to special circumstances, and do not assume legal liability. The rights of third parties must be respected. Users are advised to pay attention to the company's latest product manuals. |